Kanailal joint repair

A very fragile part of the sitar is the joint. It is the connection between the neck and the resonator. The neck (dandi) itself consists of two large parts: the flat top plate and the round bottom part. The resonator consists of three large parts: the gourd (tumba), the…

Barun Roy broken joint

One day London based sitarist & composer Jonathan Mayer drove with his car straight from London to SiTAR FAcToRY in Belgium (+/- 8hrs drive). His favorite sitar, recently made by Barun Roy, has a severe joint problem. At first sight the joint has only loosened. A friend of him…

Kabul 1900 sitar restoration – Pt2

In a first part, you can learn about this particular ancient instrument, baptised the Kabul sitar, and read a description of how to check and repair the body and make the missing wooden parts. At that time, it was already clear that other important parts were also missing: at…

Kabul 1900 sitar restoration – Pt1

In April 2020, Matyas Wolter stumbled upon some very old Indian musical instruments for sale on ebay in southern Germany. His eye fell on one of them. The description indicated that the instrument was bought in Kabul, Afghanistan, in the mid-1970s. At that time it was already considered old,…

Sarod Guitar / mod II

Ever fallen in love with a sarod but you couldn’t find one? Personally I love the sound of sarod very much but can’t play it. That’s pretty the same problem. Here’s a way out: A simple solution is to convert an existing old guitar into a Sarod guitar. In…

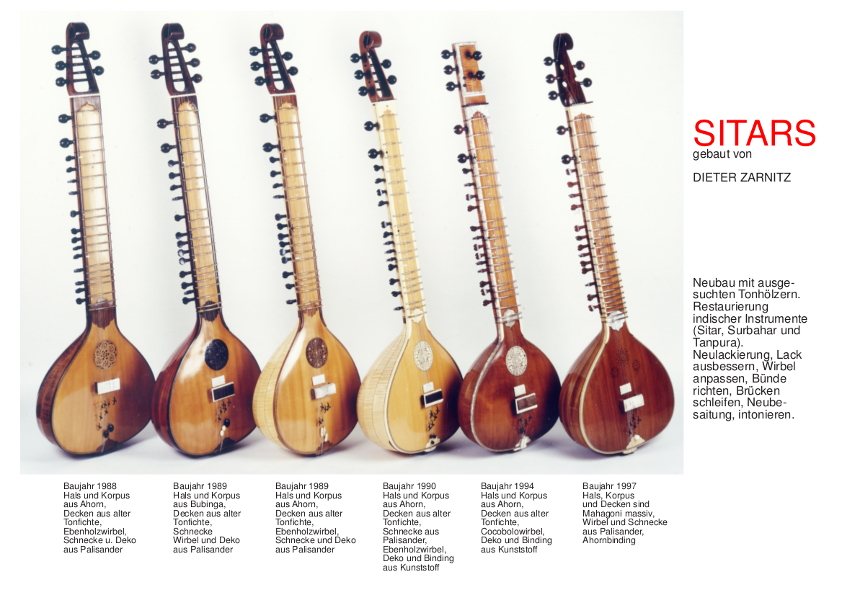

Dieter Zarnitz website

Dear friends, this year (06/2024) we sadly lost a very special and warm person, Dieter Zarnitz. He was a very talented and inventive musical instrument maker. Passionate about Indian musical instruments, he devoted his time to searching for alternatives to find a better construction and sound for the sitar…

Tom Thumb sitar

A person encounters all sorts of things in life, and so too in the sitar world. I knew that there are children’s sitars (mini sitar or baby sitar) that can also be played, but I had never seen such a gem before. What would you call it? A tiny…

Lost Paloma

This old Paloma sitar had been found in an attic. How long it stood there is not clear, but it may have been a while…. Paloma is a registered brand of Haribhau Vishwanath Diwane who distributed sitars from various builders under it. They are rather somewhat cheaper mid-range sitars…

New Narka series

I made a new set of narkas, this time from the wood of an old broomstick (aspen wood). They are done in different colours and a new SiTAR FAcToRY logo is burnt on them. My dear neighbour girl Felien Swillen is very handy with a small wood burner. She…

Rikhi Ram necklace 75′ restoration

Here then is a photo report of the work carried out: More neck bend repair can be found here.